Teknik Detaylar

Machine Features:

Higher productivity with lower cost:

Tool post structure, wider range of selectivity, and optional features provide high speed and high precision operation. This saves unnecessary expenditures.

Back spindle:

32 CSB offers high performances of front and back simultaneous machining. The simple 32 B also provides an economic solution. Not only does it maintain its functionality, but also it comes with lower cost advantage.

Orientation Function:

The 5° orientation function is standard accessory and the CF axis is optional accessory for the main spindle.

Short length of remnant material:

The Rough Material Bushing is optional. By using this rough material bushing, the remnant length can reach to 50mm (depending on the length of the last machined). It is used to reduce material waste, saving the consumption of materials.

Raw material machining :

The 0.1mm tolerance of material can also be processed on our Swiss type machine by using “Rough Material Bushing”.

Examples:

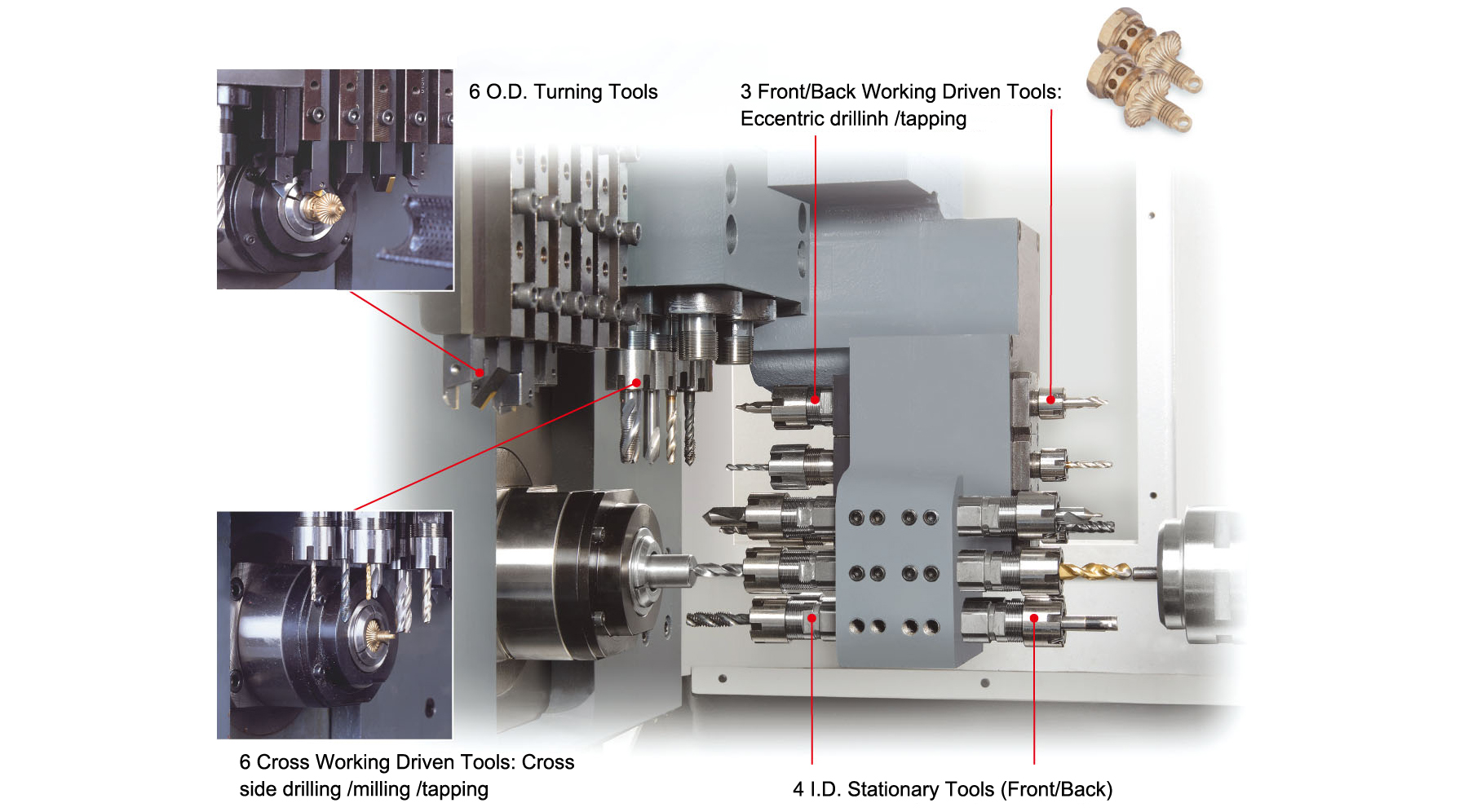

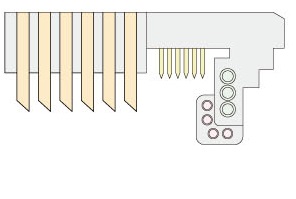

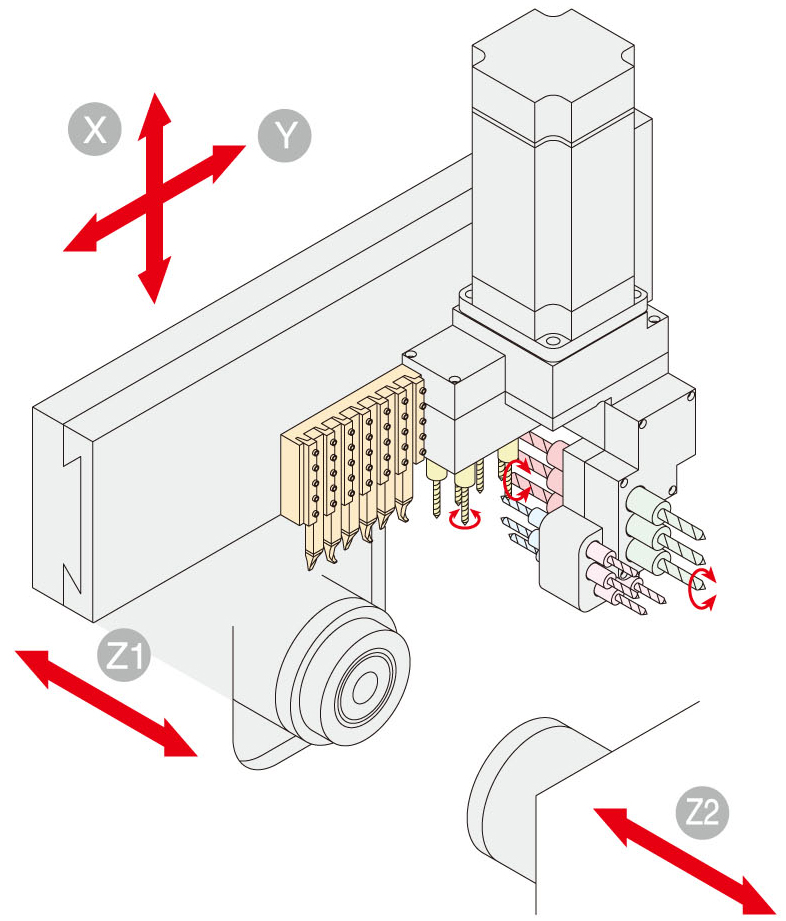

Tool Post:

Wider range of selectivity to meet your needs

O.D.

O.D.  Cross Drilling

Cross Drilling  Front I.D.

Front I.D.  Front Drilling

Front Drilling  Back I.D.

Back I.D.  Back Drilling

Back Drilling

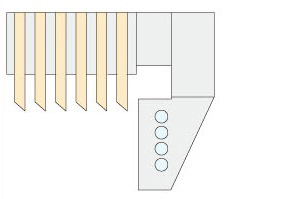

DIAMOND 32

6 O.D.Turning Tools

4 I.D. Stationary Tools

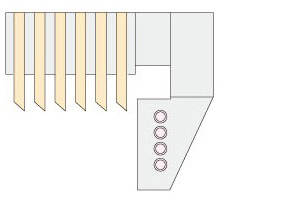

DIAMOND 32B

6 O.D.Turning Tools

4 I.D. Stationary Tools

4 Back I.D. Stationary Tools

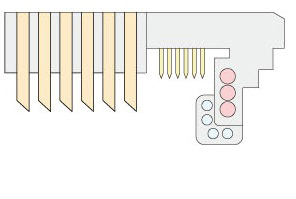

DIAMOND 32CS

5 O.D.Turning Tools

4 I.D. Stationary Tools

6 Cross Working Driven Tools

3 Front Working Driven Tools (Optional)

DIAMOND 32CSB

5 O.D.Turning Tools

4 I.D. Stationary Tools

6 Cross Working Driven Tools

3 Front Working Driven Tools

4 Back I.D. Stationary Tools

3 Back Working Driven Tools

6 O.D. Turning tool holder

6 O.D. Turning tool holder

6 Cross Working Driven Tools

6 Cross Working Driven Tools

4 I.D. Stationary Tools

4 I.D. Stationary Tools

3-Front Working Driven Tools

3-Front Working Driven Tools

4 Back I.D. Stationary Tools

4 Back I.D. Stationary Tools

3 Back Working Driven Tools

3 Back Working Driven Tools

Machine Accessories:

| Items | DIAMOND 32 | DIAMOND 32B | DIAMOND 32CS | DIAMOND 32CSB |

|---|---|---|---|---|

| Spindle 5° Indexing |  |

|

|

|

| Part off Detective Sensor |  |

|

|

|

| Coolant System |  |

|

|

|

| Work Light |  |

|

|

|

| Part Catcher |  |

|

|

|

| Live Bushing |  |

|

|

|

| Cross Working Driven Tool | – | – |  |

|

| Back Spindle | – |  |

– |  |

| Front Working Driven Tool | – | – | OP |  |

| Back Working Driven Tool | – | – | – |  |

| CF Axis | – | – | OP | OP |

| Roughing Material Bushing (Max.Machining = Bar Diameter x 3) |

OP | OP | OP | OP |

| Chip Conveyer / Chip Bucket | OP | OP | OP | OP |

: Standard – : Not Available OP : Optional

: Standard – : Not Available OP : Optional

Machine Specifications:

| Items | DIAMOND 32B | |

|---|---|---|

| Working Range | Max. Machining Dia. | Ø33 mm |

| Max. Machining Length Per Chucking | 250 mm | |

| Max. Drilling Dia. | 26 mm | |

| Max. Tapping Dia. | M12 | |

| O.D. Tooling | Number of Tools | 6 |

| Dimension | □16 ×16 ×120 | |

| I.D. Tooling | Number of Tools | 4 |

| Dimension | 13 mm (ER20) | |

| Cross Working Driven Tooling | Number of Tools | – |

| Dimension | – | |

| Cross Spindle Speed | – | |

| Front Working Driven Tooling | Number of Tools | – |

| Dimension | – | |

| Spindle Speed | – | |

| Back I.D. Tooling | Number of Tools | 4 |

| Dimension | 13 mm (ER20) | |

| Back Working Driven Tooling | Number of Tools | – |

| Dimension | – | |

| Spindle Speed | – | |

| Spindle | Bore of Spindle | Ø36 mm |

| Spindle Speed | 200- 8000 r.p.m. | |

| Back Spindle | Back Spindle Hole Dia. | Ø33 mm |

| Back Spindle Speed | 6000 r.p.m | |

| Max. Length for Front Ejection | 80 mm | |

| Rapid Speed | Rapid Speed | 18 M |

| Motors | Spindle Motor | 5.5 kw |

| Back Spindle Motor | 1.5 kw | |

| X1, Y1, Z1 Axis Motor | 0.5 kw | |

| Z2 Axis Motor | 0.5 kw | |

| Coolant Pump | 0.55 kw | |

| Lubrication | 4 w | |

| Cross Spindle | – | |

| Machine Dimensions | Center Height | 960 mm |

| Weight | 2770 kg | |

| Machine Dimension | 2550 × 1140 × 1568 mm | |

| Air Pressure | Air Pressure | 5 kg/cm |

| Air Supply | 10 L/min | |

* We reserve the rights to change the design without any prior notification.