Teknik Detaylar

Machine Features

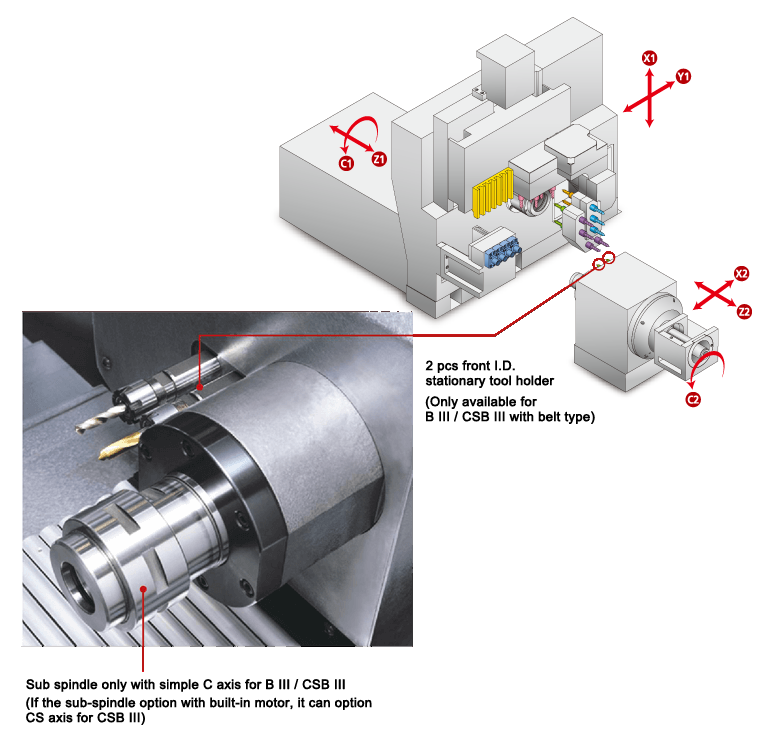

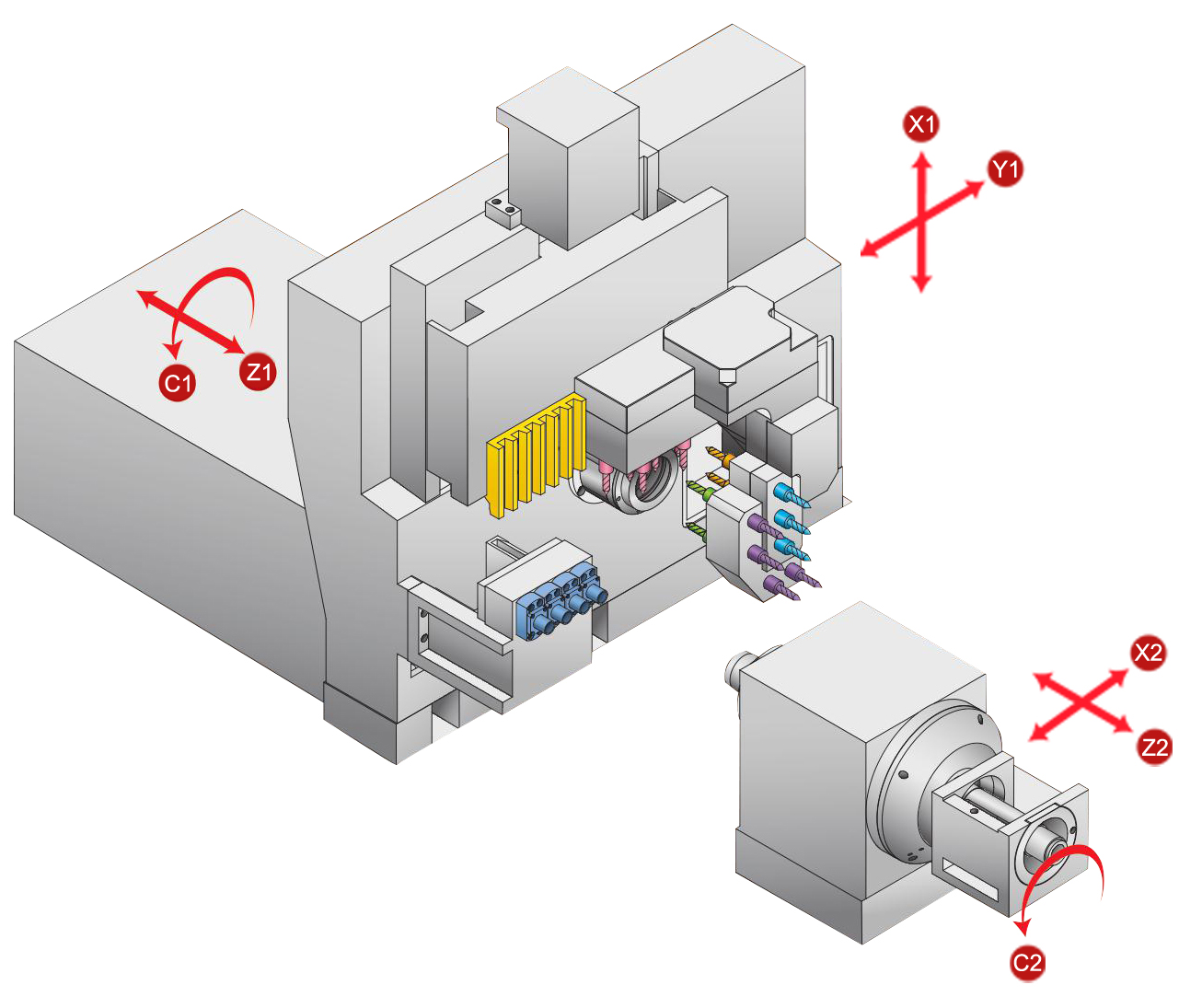

Cross travel sub-spindle :

Cross travel sub-spindle design. The main and sub spindles can work either one at a time or simultaneously for reduced machining duration. This design brings multi-function front and rear machining.

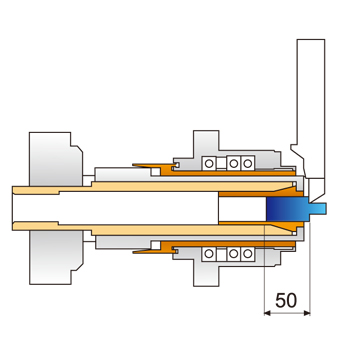

Short remnant material :

With the optional rough material bushing, the remnant material can be 50mm (depending on the part length).

Raw material machining :

0.1mm material tolerance can be achieved by using the Rough material bushing.

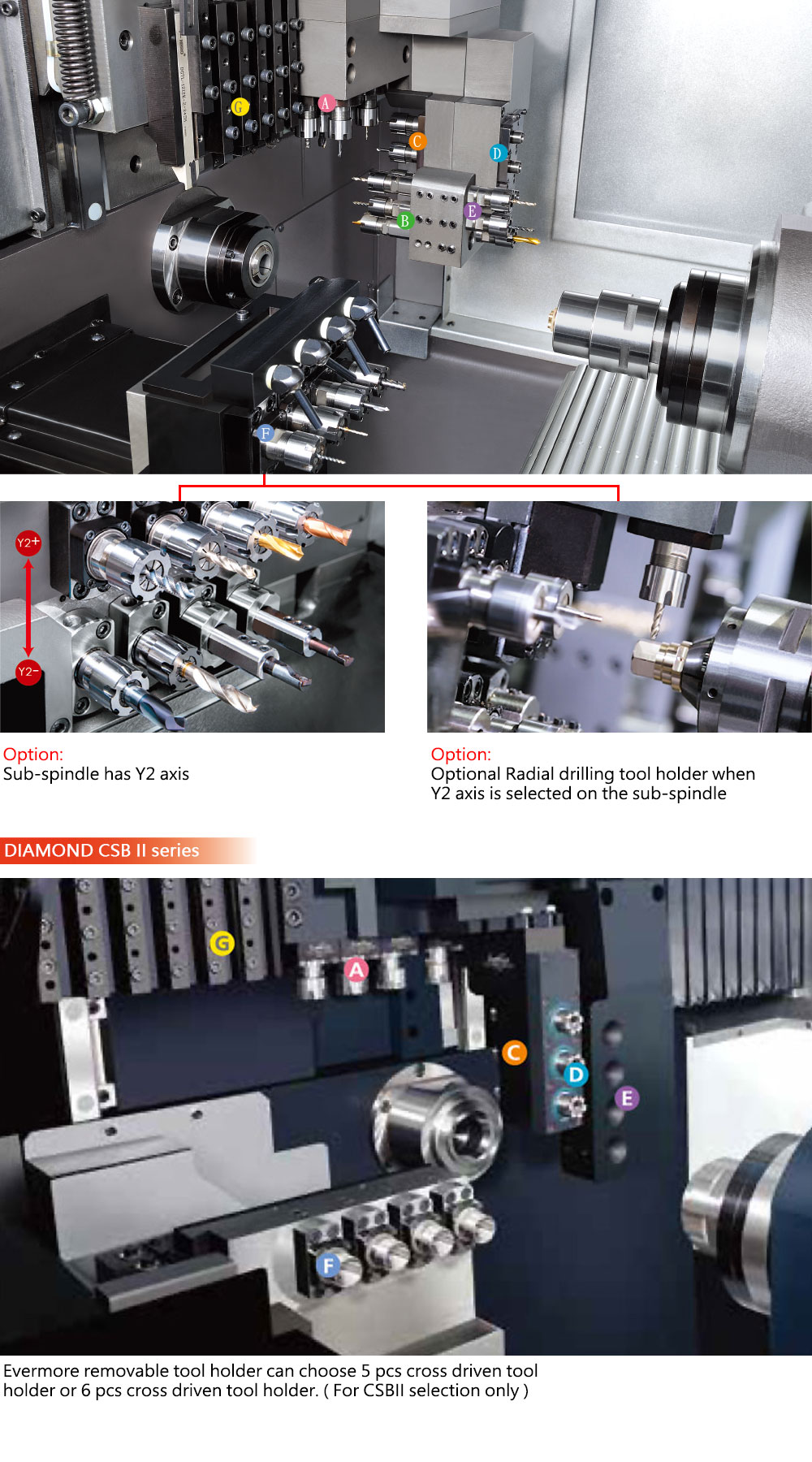

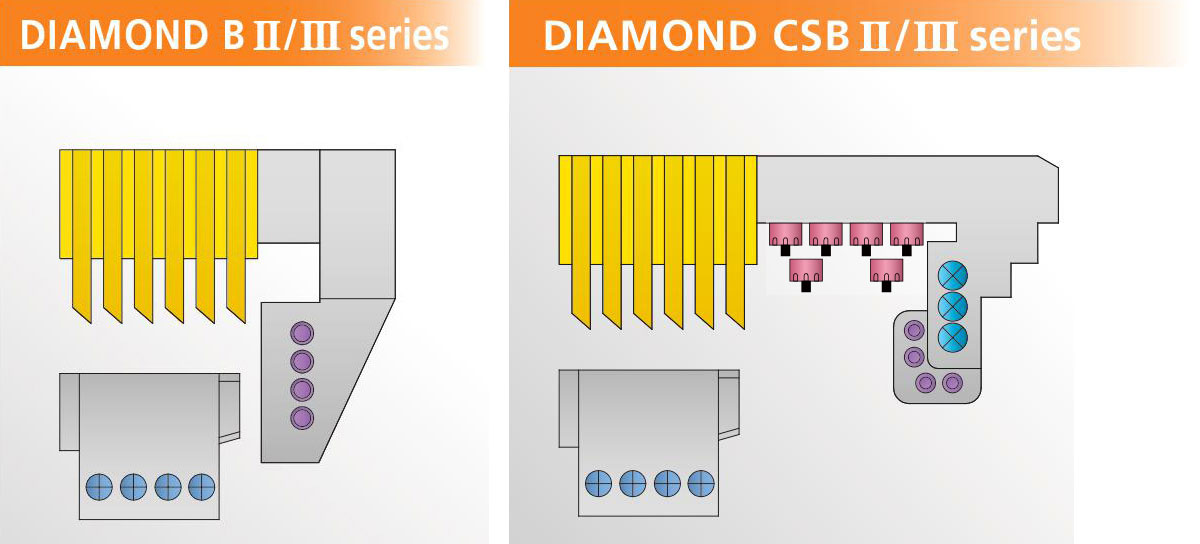

Replaceable fixed / Driven toolholder set :

The 4 pc back stationary / driven tool holder is replaced by the newly designed replaceable fixed tool holder or driven tool holder. This enables increased tooling fiexibility.

Swiss Lathe Machine Examples:

6 pcs cross working driven tool holder

6 pcs cross working driven tool holder

4 pcs I.D. stationary tool holder

4 pcs I.D. stationary tool holder

3 pcs front working driven tool holder

3 pcs front working driven tool holder

3 pcs back working driven tool holder

3 pcs back working driven tool holder

4 pcs back I.D. stationary tool holder

4 pcs back I.D. stationary tool holder

4 pcs back I.D. stationary / working driven tool holder

4 pcs back I.D. stationary / working driven tool holder

6 pcs O.D. turning tool holder (42Type with5 pcs O.D. turning tool)

6 pcs O.D. turning tool holder (42Type with5 pcs O.D. turning tool)

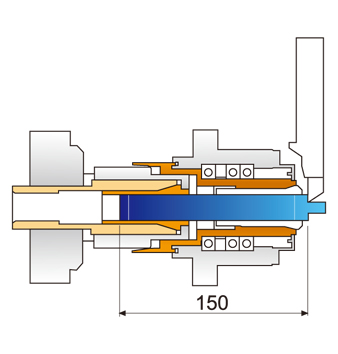

Using Live Bushing with Guide Bush

Remnant Material 150 mm

Using Rough Material Bushing without Guide Bush

Remnant Material 50 mm

Standard Accessories:

Controller: Mitsubishi

Controller: Mitsubishi Main spindle

Main spindle Back spindle

Back spindle Work light

Work light Coolant system

Coolant system Part off detective sensor

Part off detective sensor Fixed bushing (Except 32B Ⅱ/ 32CSB Ⅱ/ 42B Ⅱ/ 42 CSB Ⅱ)

Fixed bushing (Except 32B Ⅱ/ 32CSB Ⅱ/ 42B Ⅱ/ 42 CSB Ⅱ) Live bushing

Live bushing Part catcher

Part catcher

6 pcs O.D. turning tool holder(42 Type with5 pcs O.D. turning tool)

6 pcs O.D. turning tool holder(42 Type with5 pcs O.D. turning tool) 4 pcs I.D. stationary tool holder

4 pcs I.D. stationary tool holder 6 pcs cross working driven tool holder

6 pcs cross working driven tool holder 3 pcs front working driven tool holder

3 pcs front working driven tool holder 4 pcs back I.D. stationary tool holder

4 pcs back I.D. stationary tool holder 3 pcs back working driven tool holder

3 pcs back working driven tool holder 4 pcs back I.D. stationary / working driven tool holder

4 pcs back I.D. stationary / working driven tool holder

Optional Accessories:

Controller: Fanuc

Controller: Fanuc CS axis

CS axis Rough material bushing(without guide bush)

Rough material bushing(without guide bush)

Chip conveyor + bucket

Chip conveyor + bucket 2 pcs front I.D. stationary tool holder

2 pcs front I.D. stationary tool holder- (available for B III / CSB III with belt type)

Y2 Axis

Y2 Axis

Machine Specifications:

| Items | DIAMOND 12B Ⅲ |

DIAMOND 12CSB Ⅲ |

DIAMOND 16B Ⅲ |

DIAMOND 16CSB Ⅲ |

DIAMOND 20B Ⅲ |

DIAMOND 20CSB Ⅲ |

DIAMOND 25B Ⅲ |

DIAMOND 25CSB Ⅲ |

|

|---|---|---|---|---|---|---|---|---|---|

| Working Range | Max. Machining Dia. | Ø12.7 mm | Ø12.7 mm | Ø16.5 mm | Ø16.5 mm | Ø20 mm | Ø20 mm | Ø26 mm | Ø26 mm |

| Max. Machining Length Per Chucking | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | |

| Max. Drilling Dia. (Main Spindle) |

Ø7 mm | Ø7mm | Ø10 mm | Ø10 mm | Ø10 mm | Ø10 mm | Ø10 mm | Ø10 mm | |

| Max. Drilling Dia. (Sub Spindle) |

Ø7mm | Ø7mm | Ø7 mm | Ø7 mm | Ø7 mm | Ø7 mm | Ø7 mm | Ø7 mm | |

| Max. Tapping Dia. (Main Spindle) |

M6 | M6 | M8 | M8 | M8 | M8 | M8 | M8 | |

| Max.Tapping Dia. (Sub Spindle) |

M6 | M6 | M6 | M6 | M6 | M6 | M6 | M6 | |

| O.D.Tooling | Number of Tools | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Dimension | □12 × 12 × 120 | □12 × 12 × 120 | □12 × 12 ×120 | □12 × 12 × 120 | □12 × 12 × 120 | □12 × 12 × 120 | □12 × 12 × 120 | □12 × 12 × 120 | |

| I.D. Tooling | Number of Tools | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Dimension | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | |

| Cross Working Driven Tooling | Number of Tools | – | 6 | – | 6 | – | 6 | – | 6 |

| Dimension | – | 10 mm (ER16) | – | 10 mm (ER16) | – | 10 mm (ER16) | – | 10 mm (ER16) | |

| Speed | – | 200-6000 r.p.m. | – | 200-6000 r.p.m. | – | 200-6000 r.p.m. | – | 200-6000 r.p.m. | |

| Front Working Driven Tooling | Number of Tools | – | 3 | – | 3 | – | 3 | – | 3 |

| Dimension | – | 10 mm (ER16) | – | 10 mm (ER16) | – | 10 mm (ER16) | – | 10 mm (ER16) | |

| Speed | – | 200-6000 r.p.m. | – | 200-6000 r.p.m. | – | 200-6000 r.p.m. | – | 200-6000 r.p.m. | |

| Back I.D. Tooling | Number of Tools | 4+4 | 4+4 | 4+4 | 4+4 | 4+4 | 4+4 | 4+4 | 4+4 |

| Dimension | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | 10 mm (ER16) | |

| Back Working Driven Tooling | Number of Tools | – | 3 | – | 3 | – | 3 | – | 3 |

| Dimension | – | 7 mm (ER11) | – | 7 mm (ER11) | – | 7 mm (ER11) | – | 7 mm (ER11) | |

| Number of Tools | – | 4 | – | 4 | – | 4 | – | 4 | |

| Dimension | – | 10 mm (ER16) | – | 10 mm (ER16) | – | 10 mm (ER16) | – | 10 mm (ER16) | |

| Speed | – | 200~6000 r.p.m. | – | 200~6000 r.p.m. | – | 200~6000 r.p.m. | – | 200~6000 r.p.m. | |

| Spindle | Spindle Hole Dia. | Ø13 mm | Ø13 mm | Ø17 mm | Ø17 mm | Ø22 mm | Ø22 mm | Ø27 mm | Ø27 mm |

| Spindle Speed | 200- 8000 r.p.m. | 200- 8000 r.p.m. | 200- 8000 r.p.m. | 200- 8000 r.p.m. | 200- 8000 r.p.m. | 200- 8000 r.p.m. | 200- 8000 r.p.m. | 200- 8000 r.p.m. | |

| Main Spindle Indexing Angle | C axis | C axis | C axis | C axis | C axis | C axis | C axis | C axis | |

| Back Spindle | Spindle Hole Dia. | Ø13 mm | Ø13 mm | Ø17 mm | Ø17 mm | Ø22 mm | Ø22 mm | Ø27 mm | Ø27 mm |

| Spindle Speed | 200-5000 r.p.m (200-8000 r.p.m Optional built-in motor) | ||||||||

| Max. Length for Front Ejection | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm | |

| Sub Spindle Indexing Angle | C axis | C axis | C axis | C axis | C axis | C axis | C axis | C axis | |

| Rapid Traverse | X1, Y1, Z1, X2, Z2 | 30 m/min | 30 m/min | 30 m/min | 30 m/min | 30 m/min | 30 m/min | 30 m/min | 30 m/min |

| Motors | Spindle Motor | 2.2 kw | 2.2 kw | 2.2 kw | 2.2 kw | 3.7 kw | 3.7 kw | 3.7 kw | 3.7 kw |

| Back Spindle Motor | 2.2 kw (2.2 kw Optional built-in motor) | 2.2 kw (3.7 kw Optional built-in motor) | |||||||

| X1, Y1, Z1, X2, Z2 Axis Motor | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | |

| Y2 Axis Motor | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | 1 kw | |

| Coolant Pump Motor | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | 1 HP | |

| Lubrication Motor | 4 w | 4 w | 4 w | 4 w | 4 w | 4 w | 4 w | 4 w | |

| Driven Tools Motor-fixed Arm | – | 2.2 kw | – | 2.2 kw | – | 2.2 kw | – | 2.2 kw | |

| Driven Tools Motor-back Replaced Toolholder Set | – | 1.5 kw | – | 1.5 kw | – | 1.5 kw | – | 1.5 kw | |

| (Option Y2 Axis) | – | 2.2 kw | – | 2.2 kw | – | 2.2 kw | – | 2.2 kw | |

| Machine Dimensions | Center Height | 890 mm | 890 mm | 890 mm | 890 mm | 890 mm | 890 mm | 890 mm | 890 mm |

| Weight | 1890 kg | 1920 kKg | 2040 kg | 2070 kg | 2090 kg | 2120 kg | 2140 kg | 2170 kg | |

| (Optional Y2 Axis) | 2300 kg | 2450 kg | 2500 kg | 2550 kg | |||||

| Machine Dimension | 2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

2440 × 1430 × 1650 mm (2690 x 1495 x 1890 Optional Y2 Axis ) |

|

| Air Pressure | Air Pressure | 5 kg/cm | 5 kg/cm | 5 kg/cm | 5 kg/cm | 5 kg/cm | 5 kg/cm | 5 kg/cm | 5 kg/cm |

| Air Supply | 10 L/min | 10 L/min | 10 L/min | 10 L/min | 10 L/min | 10 L/min | 10 L/min | 10 L/min | |

* We reserve the rights to change the specs below without any prior notification.